Using milking solutions with stimulation and controlled pulsation to get the milk flowing, and flowing right.

Shortened milking time, more reliable milking, improved cow comfort, and more operator convenience are just some of the benefits derived from advanced milking solutions with automated stimulation and dynamic pulsation.

As dairy farms grow and the demand for milk increases, better milk flow management has become crucial for cow comfort and health, as well as for overall efficiency. One way to help make the process smoother is to use milking solutions with stimulation and controlled pulsation to get the milk flowing, and flowing right.

Stimulation and controlled pulsation implemented together in an automated milking solution help:

- Shorten milking time

- Eliminate over-milking and teat irritation

- Improve operator and cow wellbeing

- Compensate for poor/short preparation

Let’s explore how this works.

What is stimulation and why is it needed?

20% of the milk yielded by dairy cows is stored within its ducts and cisterns and needs to be let down into the teats to get milk flowing. But it’s not always easy getting a cow to let down her milk. That’s why stimulation is needed.

You can stimulate the cow’s natural oxytocin hormone to release milk by wiping the teat clean or by massaging the teat for at least 15 seconds. But, with traditional milking solutions, it’ not always clear when to begin stimulation.

That’s why an automated milk measurement solution, in which the system accurately assesses the flow rate in the first few seconds can help. This way, if the system sees that milk hasn’t begun flowing or hasn’t reached the desired threshold in say, 30 seconds, it can trigger automatic stimulation so that the cow will let her milk down faster.

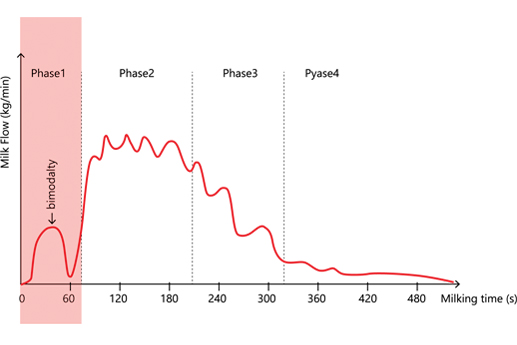

An example of the effects of controlled stimulation on milk flow. If milk doesn’t start flowing within 30 seconds (i.e. less than 1kg of milk per minute), automatic stimulation begins with high frequency pulsations (300 PPM) for 30 seconds, or until milk starts flowing

Where does automated pulsation fit in?

Stimulation in a way is actually an outcome of a type of pulsation. A pulsator, after all, essentially represents the way the cow naturally sucks on the teat, i.e. a pull and release motion. And a stimulator comes into effect when this motion either isn’t affecting milk letdown at all, or not fast enough. This simulation-pulsation loop is an essential component in all advanced milking solutions, but with the Allflex MC200 milking controller, the pulsator’s usefulness goes one step further.

With unique real-time measurement technology, the system not only knows when and how to stimulate the cow, it also knows how to adapt its pulsation rate throughout each milking stage, per individual cow.

Some companies have a trigger button to create a higher pulsation. But the Allflex system is automatic, and that makes a big difference. For starters, it learns each cow in the parlor and addresses the right pulsation to that cow, automatically, making milking sessions increasingly efficient over time.

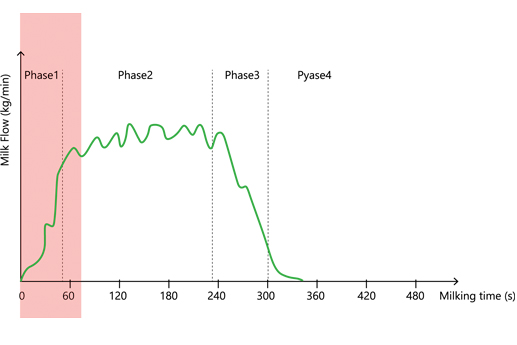

In addition, the flow meter together with the controller can automatically adjust pulsation during any milking session according to the real-time milk flow. For example, if the milk flow increased, then the pulsation will slow in turn – say from 60/40 at 60 ppm to 70/40 on 55 ppm work/rest rate – to draw out more milk per pull. This reduces machine on-time and is easier on the cow’s teats.

Flow rate vs. pulsation ratio. As milk flow increases pulsation slows.

The same is true at the beginning of a milking session, going back to our point above, in which pulsation is automatically triggered based on a precise formula of seconds passed and yield. For example, in most cases, milk flow below 1 kilogram per minute triggers the auto pulsation at the beginning of milking. This makes each milking session more productive and gentler for the cow.

Similar to what happens at the beginning of milking, at the end of a session an automated system detects that the milk has gone below a certain threshold. It then starts blinking fast-to make sure the cow is actually on a drop time, and not a temporary break – and begins automatic take-off or cluster removal accordingly.

This take-off accuracy is particularly significant when you consider how the front teats finish first, and what that means to milk yield if you’re not accurately doing both the front and the back removal before stabilizing. A fill and dump system needs about 20-40 seconds to know when to remove, while the Allflex system needs only five seconds. It’s not a race of course, but precisely timed cluster removal is another key way to speed up the process while preventing teat irritation and udder damage from over-milking.

The best milking solutions work as one

Bottom line, stimulation and pulsation have evolved over time into a near-exact science that can help make milking more productive for each and every cow. And while it’s possible to choose just one or the other, the reality is that stimulation and controlled pulsation work best hand-in-hand. More so, the best total milking solutions are those in which all parts work in unison.

Needless to say, technology alone is not enough. A productive farm needs constant human monitoring and a strong management team. But a full solution that includes automated stimulation and pulsation, individual ID assignment to each cow, and an automatic milk measurement system can help keep your cows healthier and your farm more profitable.